|

|

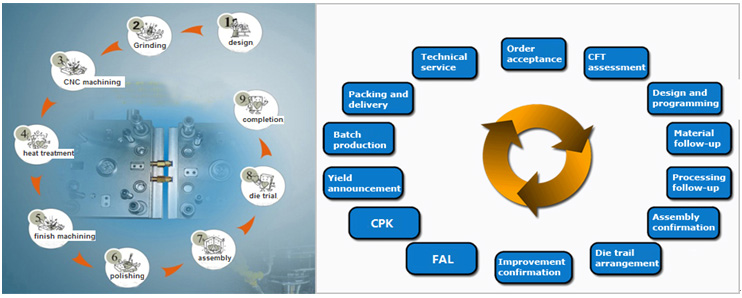

Details Plastic Injection MoldingIntroduce: process for producing parts from plastic materials and is widely used for a variety of parts, from the smallest component to entire body panels for vehicles such as home appliance mould (which named household injection mold or houseware mold),kitchen ware mould, ems plastic mould, automobile tools mould, home appliance tool mould, solar generator mold, medical tools mold and other ABS / PC / PP /POM material plastic Insert Injection Molding products. After a plastic product is designed, usually by an industrial designer or an engineer, injection molds are made by a mold maker from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part. Plastic is then fed into a heated barrel, mixed, and injected into a mold cavity where it cools and hardens to the shape of the injection mold. With the use of plastic parts on the rise in almost every industry, combined with growing pressure to reduce costs and cut time to market, the need for plastic injection molding simulation tools that provide deep insight into the plastic injection molding process has never been greater. Mold Material: 45#, P20, 718, 718H, H13, 2738, 2316, NAK80, S316 Why us: Team: Lancor has a team of professionals in engineering plastic injection molding industry, which has its production bases in Ningbo, Shenzhen, Suzhou city. Lancor has successfully undergone a continuous expansion, merging state-of-the-art machinery technology and highly skilled staff. Having adopted "improvement of technology and communication as well as achievement of one hundred percent quality" as our motto, all staff members of our Lancor team are making constant tireless efforts to give our customers greater satisfaction. Procedure:  Design: -An integrated design system, from the industrial design to mechanism design and mold design -3D CAD / CAM lineup for wide range support of data formats -Fine flow analysis by Moldflow -Accurate rapid design development with techniques and know-how in full use -Online data communication -Tightly knit cooperation between sales and manufacturing Mold Manufacture: -Equipped with the large capacity of up-to-date machine tools -Precision machining on the sub-micron order -Stress-free smooth process and speedy delivery -Complete maintenance Assembly: λ.Assembly to semi-finished products λ.Disciplined standardized work λ.Heat staking, ultrasonic welding λ.Clean room assembling line Quality Assurance: -Highly skilled workforce -Frequent educational trainings and meetings for information exchange -A visual inspection is performed by our trained machine operators on every part that is made the moment it comes out of our machine using the parameters and critical dimensions set by you, our customer, to identify any rejects. -Information feedback to manufacturing division -The injection mold parts are then randomly inspected once again by our QA personnel at the machine once every hour, and any rejects are logged. -The acceptable parts are boxed, counted, and moved to our quality control department, where they are randomly inspected once again, and the count is verified. The parts are then ready for shipment. -High yield rate and on time delivery. Whom we service: We are a mold designer & manufacture by virtue of its professional skills and high-class services, has won unanimous praises from customers, with our customers to transform their design into a finished product. Its products cover home appliances, laptop parts, electronic components, connectors, automotive parts, motors, medical equipment parts, pipe joints, sanitary ware parts, etc. According to customers’ needs, it can produce plastic mould in compliance with HASCO, DME, and MISUMI standards, And the plastic injection mold have been exported to the United States, France, Switzerland, Germany, Italy, Japan, etc. Small Household Appliance Mold:  Back If this product Not the products you want: Mail , Or click here Post a buy information about product to us. |